Engineering poster fair showcases internship experiences

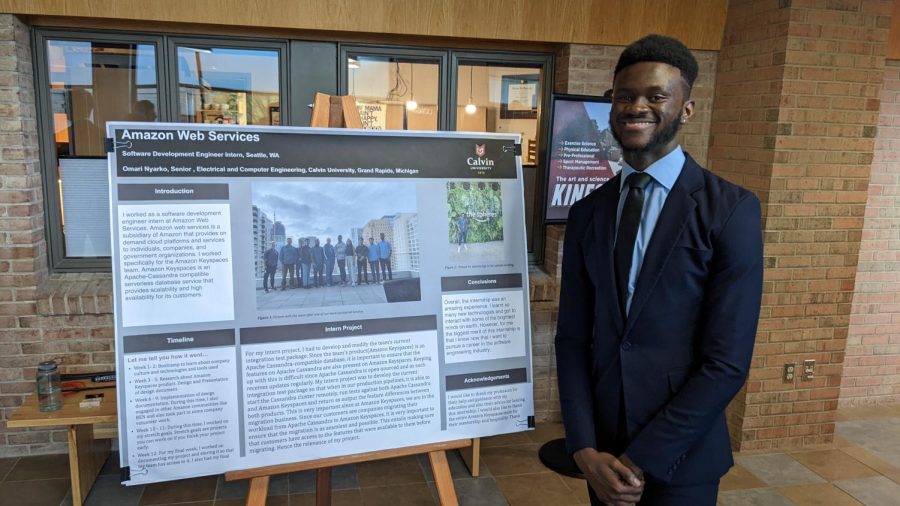

Omari Nyarko interned at Amazon Web Services where he helped customers be able to seamlessly integrate their data into database services.

According to Engineering Internship Coordinator Jessica Noble, 32 seniors and nine juniors presented at the engineering department’s annual poster fair this year. The fair is an opportunity for students to showcase the work they did during their summer internship or research. From improving conditions for manufacturing workers to saving companies thousands of dollars, student interns made a big impact in a variety of fields while gathering work experience.

A wide spectrum of experiences

The annual fair featured internships at a variety of organizations, including information technology companies like Amazon Web Services, manufacturing companies like General Motors, Flexco and Haworth Inc., and architectural companies like AECOM.

Goals of student’s projects included making technology more efficient, safe, user-friendly and cost effective. A number of students worked on making a technology more optimal for both employee and consumer use. Others worked on optimizing the expenditure of a company’s funds and resources, and still others spent their summers working on quality control.

Junior mechanical engineering student Sam Mennega interned at Flexco, a manufacturing company focused on conveyor belt production and solutions. His work focused on improving the life conditions of the company’s manufacturing team. “Our goal was to make life as safe and conducive for the team as possible,” Mennega said, and he played a crucial role in designing equipment that now makes the environment of the construction and manufacturing workers at Flexco safer.

Senior electrical and computer engineering student Omari Nyarko spent his summer at Amazon Web Services. He was involved in the development of an integration testing package that enabled consumers to make straightforward and seamless integration of data into their database services.

Several engineering students completed research focused on cost effectiveness.

Nana Ama Atobrah, a senior studying electrical and computer engineering, collected and analyzed data to investigate how Haworth, a furniture manufacturing company in Holland, MI, was allocating its time and resources. Atobrah was able to ultimately present cost-effective solutions that could save the company about $11,200 a day.

William Toomey, a senior studying chemical engineering, focused on optimizing products. In his role at General Motors, he inspected the quality of products that were provided to consumers, and relayed feedback on issues found as well as solutions to those issues.

An opportunity to learn and grow

Engineering 295, an internship workshop course designed to help students navigate their way through a summer internship, is a requirement for admission to a concentration in the engineering program. The department feels it is essential for engineering students to get hands-on experience in a field that they are interested in.

Hands-on experience helps students with “determining what concentration they want to pursue … developing a network of professionals … gain[ing] experiential learning … [all] by being in a real world setting and starting to apply those concepts that they’re learning in class,” Noble said.

Internships show students the reality of the careers that they are interested in, which sometimes means they adjust their plans, according to Noble. “That they don’t have that additional drive for doing the design work, or they find that they really like [a different] specific science field better once they get to college … I find that a lot of times it’s just they don’t necessarily know what engineering entails,” Noble said.